Insulated building "SteelCombi"

Insulated buildings

Main frame type

The main frame is a I-beam profile construction, manufactured in the factory from steel sheets, the surface of which is prepared according to the ISO 8501-1 standard up to class SA2, primed with a 40 µm thick layer of special paint and coated with a 40 µm thick paint layer. Individual load-bearing structure elements are connected with rigid joints, using bolts of strength class not lower than 8.8. To ensure the rigidity of the building, transverse horizontal connections are used – Z and C type profiles made from galvanized steel. The load-bearing structure is anchored to the foundation with anchor bolts. The foundation must be installed based on the characteristics of the prevailing soils in the area and the minimum requirements provided by the structure manufacturer. Steel grades S235/275/355 are used in the structures. All structures are designed in accordance with strict LST EN standards

SteelCombi

ButtonSteel buildings – dimensions

The width of SteelCombi without internal supports can reach 60 m. With columns inside the building, the width and length would be unlimited. The wall height of SteelCombi can reach 15 m. The most popular standard buildings are typically 15-20 m wide with a wall height of 4-6 m

Wall and roof covering

The uninsulated SteelCombi hangar is covered with profiled sheet metal. In cases where an insulated hangar is required, it is covered with multi-layer panels. The basic SteelCombi configuration usually includes a multi-layer panel with polyurethane insulation. The most popular insulation layer in Lithuania is 100 mm. Below are the technical specifications of the multi-layer panels. The price of the hangars heavily depends on the chosen insulation material

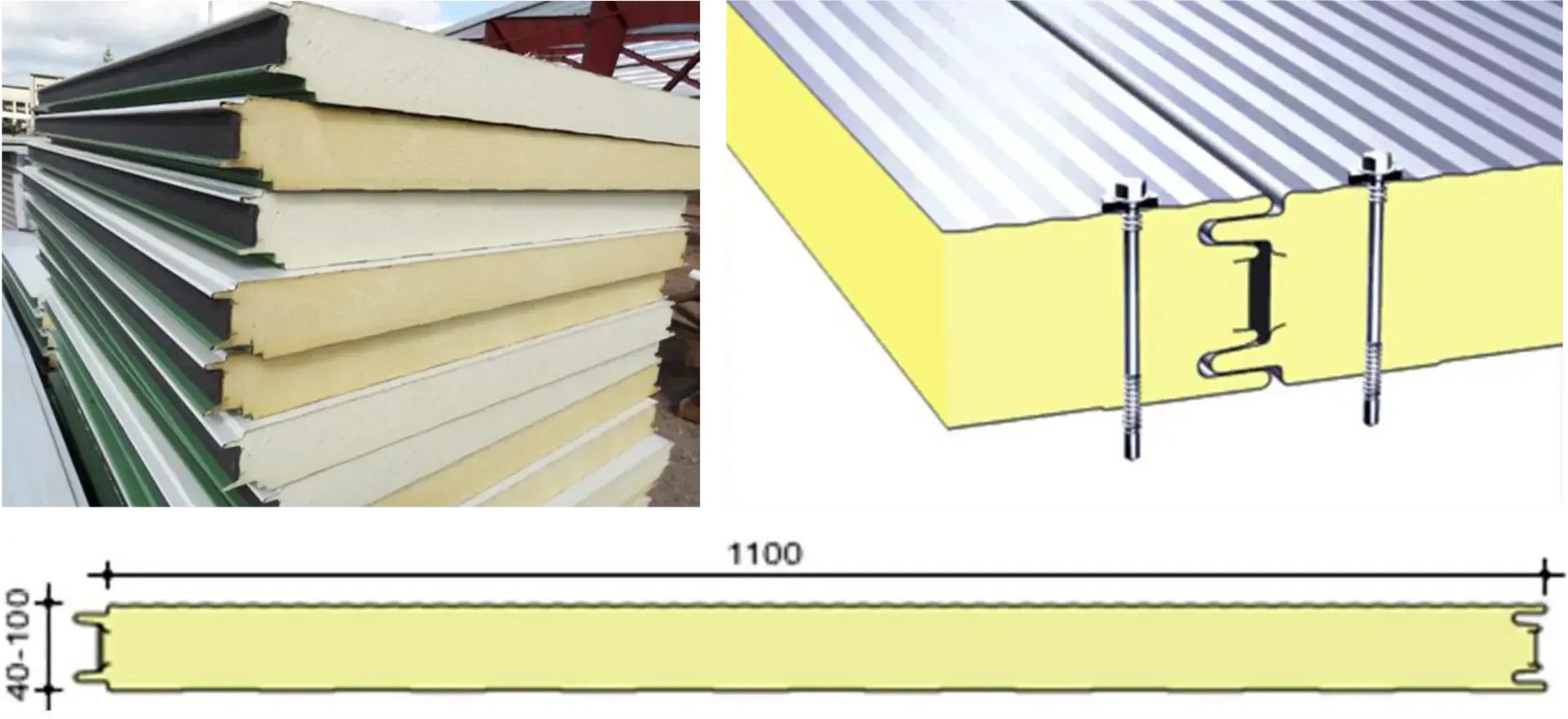

Standard sandwich panels for walls

- Filling: rigid polyurethane foam

- Density: 40 (±3)

- Panel thickness: mm 40, 50, 60, 80, 100

- Weight: (kg/m) 10.26; 11.08; 11.58; 11.79; 12.60

- Coefficient: Uo [W/m K] 0.55; 0.44; 0.37; 0.28; 0.22

- Construction width: 1100 mm

- Thickness of inner and outer sheets: mm, from 0.4 to 0.63 mm

- Profiling of outer sheets: L – linear, M – microprofiling, G – smooth

- Profiling of inner sheets: L – linear, G – smooth

- Coating of outer sheets: POLYESTER, POLIMAT, HPS, PVDF

- Coating of inner sheets: POLYESTER, HPS, AlZn, stainless steel

- Min/max length: min=2.5 m max=18 m

- Standard colors of outer sheets: RAL 3016, 3011, 8012, 8017, 9005, 9010, 1015, 1017, 1003, 7024, 6011, 6020, 6005, 9007, 5010, 7035, 9006, 9002, Zn, AlZn, stainless steel

- Steel: S280GD Z275

- Stainless steel: OH18N9

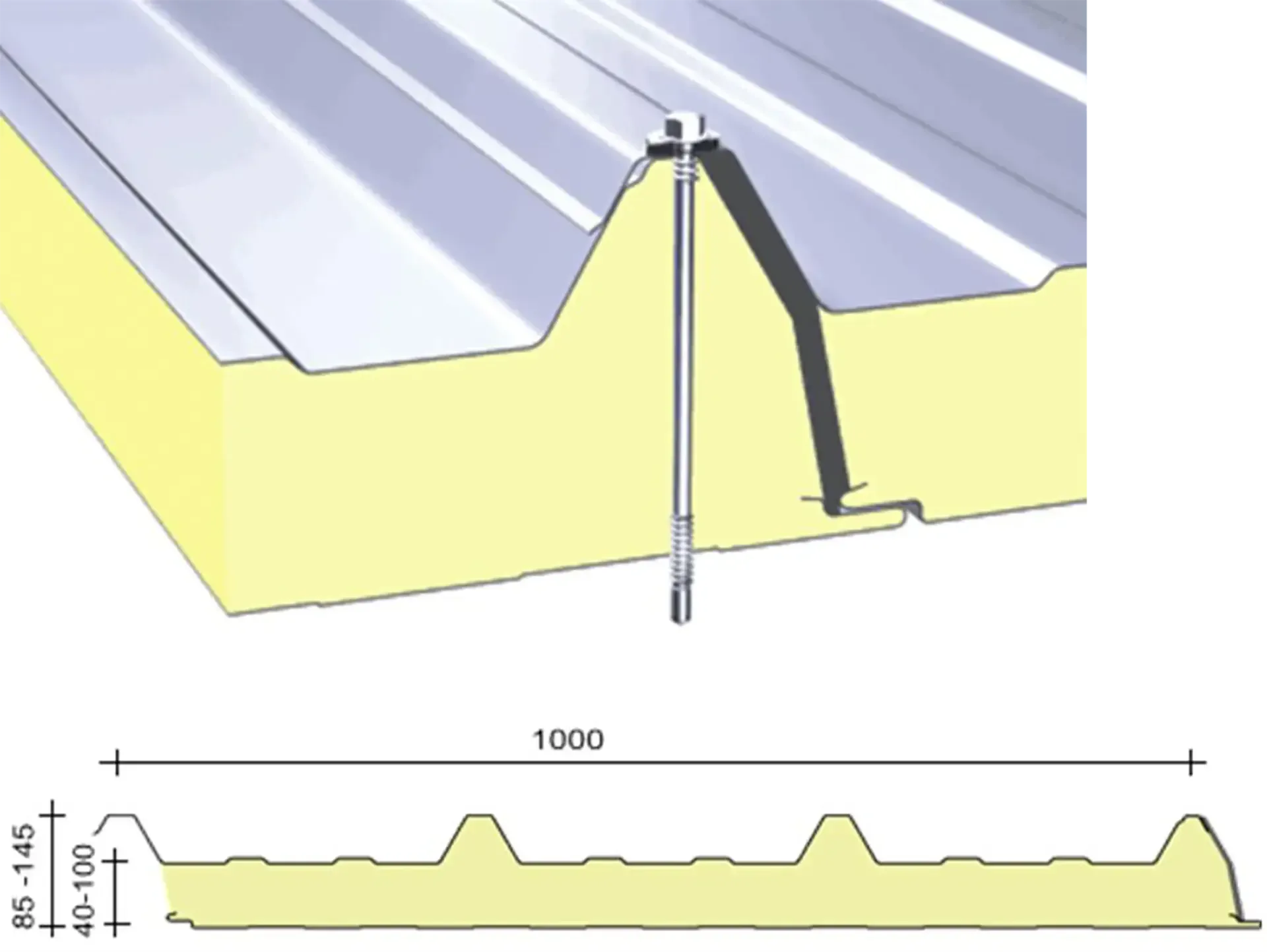

Standard sandwich panels for roof

- Filling: rigid polyurethane foam

- Density: 40 (±3)

- Panel thickness: mm 40/85, 60/105, 80/125, 100/145

- Weight: (kg/m) 10.84; 11.65; 12.45; 13.26

- Coefficient: Uo [W/m K] 0.5; 0.35; 0.27; 0.22

- Construction width: 1000 mm

- Thickness of inner and outer sheets: mm from 0.4 to 0.63 mm

- Profiling of inner sheets: L – linear, M – microprofiling, G – smooth

- Coating of outer sheets: POLYESTER, POLIMAT, HPS, PVDF, Aluzinc easyfilm®, zinc

- Coating of inner sheets: POLYESTER, HPS, Aluzinc easyfilm®, zinc, stainless steel

- Min/max length: min=2.5 m max=18 m

- Standard colors of outer sheets: RAL 3016, 3011, 8012, 8017, 9005, 9010, 1015, 1017, 1003, 7024, 6011, 6020, 6005, 9007, 5010, 7035, 9006, 9002, Zn, AlZn, stainless steel

- Steel: S280GD Z275

- Stainless steel: OH18N9

Gates and doors

The base package price always includes one overhead Additional gates, windows, and doors.

- Skylights

- Turbine ventilators

- Fire escape ladders

- Second-floor decking

- Lighting

- Crane beam

- gate with built-in hinged doors.

SteelCombi

Button

Navigation

All rights reserved | Ekoangarai, LTD | Cookie Policy | Change cookie settings | Created by: www.saulesspektras.lt